#5's

#6's

Riser wall panels

Cupola wall panels

Cupola roof panels

Loft dormers

1st floor dormer

#6's

Riser wall panels

Cupola wall panels

Cupola roof panels

Loft dormers

1st floor dormer

0

0

0

0

0

3

2

0

0

0

0

3

2

11

25

20

5

5

0

0

25

20

5

5

0

0

These are the pieces we have left to complete the cabin dome.

Completed

2014

We took a break from working so many hours in the shop and spent most of last year doing more site work (logging and built wood shed). This year we will dedicate more time to working in the shop in hopes of being ready to erect the cabin complete with timber frames next spring.

5-5-14

We planted Noble fir seedlings.

We planted Noble fir seedlings.

One of many

We planted over 200 baby trees on our hillside. We'll have to thin as they grow.

4-19-14

We lost my Dad at the end of tax season this year. I wish he could be here to share in our joy of our place but I know a part of him is with us always.

We lost my Dad at the end of tax season this year. I wish he could be here to share in our joy of our place but I know a part of him is with us always.

Back to home page

Back at home we have four beautiful Redwood trees. Two of which are in the driveway and have started dropping BIG branches on top of my car and in the driveway area.

5-24-14

So we decided it was time for the two in the driveway to come down.

So we decided it was time for the two in the driveway to come down.

We hired Cassidy. He climbed, limbed, topped, then felled them.

We had two large Grand fir trees, that had been slowly dying since the flood in 1996, that were in the way so he cut them first.

The smaller of the two Redwoods is 52 inches across at the butt.

Next to come down was the big one closer to the house. Because of its proximity to the house all the limbs had to be lowered by rope.

6-2-14

He carefully made and fine tuned his undercut then felled it exactly where it was supposed to go.

He carefully made and fine tuned his undercut then felled it exactly where it was supposed to go.

It came down with an earth shaking thud. It was 60" across.

We plan to cut horizontal slabs from the two butt cuts which we will use to make our dining room table for the dome. The rest will become paneling for the great room of the dome.

6-16-14

Dan finished the #5's and with Robbie and Marty's help we loaded the trailer and took them to the dome.

Dan finished the #5's and with Robbie and Marty's help we loaded the trailer and took them to the dome.

With serendipity at work we ran into an old friend and his sons while pulled over tightening straps on our load. Keith, Andrew, & Benjamin came up to the the dome and helped us unload.

6-19-14

We decided it was time for us to take a dream vacation (other than pouring concrete or digging ditches, although those are hard to beat:). We decided on New Zealand.

We decided it was time for us to take a dream vacation (other than pouring concrete or digging ditches, although those are hard to beat:). We decided on New Zealand.

Our trip to New Zealand and Fiji

Back from vacation Dan got busy making the #6's.

7-13-14

Today Dan finished the #6's!!!! It's a milestone day for us. All the triangle panels for dome shell are now complete. Ya Ya Ya, Happy Dance, Happy Dance:) Followed by a cocktail.

Today Dan finished the #6's!!!! It's a milestone day for us. All the triangle panels for dome shell are now complete. Ya Ya Ya, Happy Dance, Happy Dance:) Followed by a cocktail.

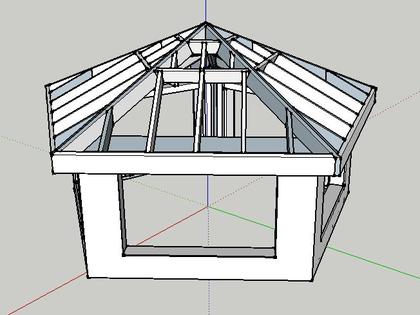

We spent a couple of evenings and drafted our cupola and riser walls.

We'll start on the cupola next.

We'll start on the cupola next.

I've been checking Craig's List for a hot tub for the dome for a while now. We will need to drop it into the basement before building the floor deck next year. This morning I found exactly the one I had been looking for. For Free. In Longview.

In less then two hours we were back home with our new (to us) hot tub.

7-17-14

Bill & Jackie from Outlaw Steel arrived with their Lucas Mill and loaded the first log into the mill.

Bill & Jackie from Outlaw Steel arrived with their Lucas Mill and loaded the first log into the mill.

Doing some calculations so as to end up with the center slab at the right spot.

I can't wait to see what the center looks like.

We are going to have several nice slabs to choose from but...

I think this next one will end up being our dining room table.

Because of the weight we can only haul four at a time.

At the house Bill loaded the slabs using his skid steer w/forks. At the dome we had to get creative to unload and stack them. We used the Genie lift, a come along, and blocks. But because they weigh around 1000 lbs each and don't fit through the door,they were still difficult!

We spent all day saturday restacking some triangles and cleaning shop to make room for the redwood.

7-24-14

All the slabs put to bed. Thank goodness!

All the slabs put to bed. Thank goodness!

Then the rest of the logs were cut into 6" slabs.

Then the slabs are loaded onto the Hud-Son band saw mill.

Four slabs are clamped together.

And then the slabs are cut into 1 x 6 boards.

After the boards have time to season Dan will make tongue and groove paneling.

Because the mill is water lubricated the boards come off with damp sawdust sticking to them. We have been cleaning them before we stack them for seasoning so they don't grow mold.

We can haul about 150 boards at a time and we have about 1000 boards. Lots of trips up the hill.

Our sawyers, Jackie and Bill,also have a metal and wood specialty store. They gifted us this sign and Dan hung it on a redwood "cookie" and we put it by our gate.

8-2-14

We used the genie lift to build our piles.

We used the genie lift to build our piles.

We decided to try to stack all the boards in two piles to save some floor space for timbers.

8-7-14

The second pile is getting higher. We have hauled eleven loads to the dome in the last three weeks.

The second pile is getting higher. We have hauled eleven loads to the dome in the last three weeks.

If Buck keeps doing stupid stuff he might be the next mount in the dome. haha

8-31-14

Finally got all the redwood boards cleaned and stacked. I thought we'd never get to the end. 1,071 boards!

Finally got all the redwood boards cleaned and stacked. I thought we'd never get to the end. 1,071 boards!

8-30-14 Hauled and stacked the #6's.

8-31-14 Starting to clear the area for the well pump / generator shed.

We're finding it sooo hard to work in the shop on these beautiful summer days. It is easy to get distracted with outdoor projects especially up at the dome site because we love being up there. We've decided we needed to break down our project into smaller goals. This will allow us to actually see a projected finish date and so Dan can do other projects outside of the shop without feeling guilty about using shop time. And.....so far so good!

August - cupola roof panels. These were a real challange. Bigger and different then all the other panels.

X

September - cupola wall panels.

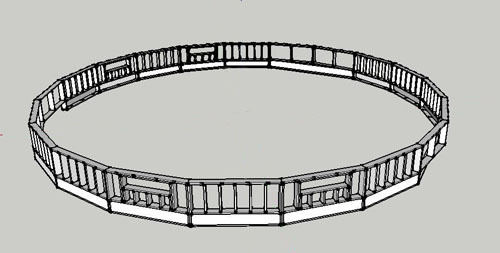

October - riser wall panels.

November - Hunting season 1st, then dormers, finish riser walls.

December - finish dormers, reconfigure shop for timber framing, build another set of timber saw horses, holidays.

2015 - start timber framing.

To estimate time needed we took the hours from one of the shop timber frames (very similar to the house frames) 268 hours and multiplied by three cabin timber frames = 804 hours. This does not count hours spent by Mike or myself of planing and sanding or the hours spent doing the fitting. Next, to find the time available from Jan 1 2015 to Feb 1 2016 (begining of tax season) we took 56 weeks substracted 12 weeks for tax season, 2 weeks for hunting season, 1 week vacation, 1 week of holidays = 40 weeks. So with 20 hours per week we will be ready to build at the end of tax season 2016.

To estimate time needed we took the hours from one of the shop timber frames (very similar to the house frames) 268 hours and multiplied by three cabin timber frames = 804 hours. This does not count hours spent by Mike or myself of planing and sanding or the hours spent doing the fitting. Next, to find the time available from Jan 1 2015 to Feb 1 2016 (begining of tax season) we took 56 weeks substracted 12 weeks for tax season, 2 weeks for hunting season, 1 week vacation, 1 week of holidays = 40 weeks. So with 20 hours per week we will be ready to build at the end of tax season 2016.

The cupola roof panels. These panels have a trim board that I'm pre painting.

9-13-14

Dan ran the wood splitter, I painted the wood shed, Ethan started stacking wood.

Dan ran the wood splitter, I painted the wood shed, Ethan started stacking wood.

9-14-14

Mike and Brandon came up to help. We have ALOT of wood to be split from all the logging we did to clear our view on the south side. Dan, Mike, & Brandon split wood and brought it up from the lower landing and Ethan and I stacked it. We got a good start but have quite a bit more to do.

Mike and Brandon came up to help. We have ALOT of wood to be split from all the logging we did to clear our view on the south side. Dan, Mike, & Brandon split wood and brought it up from the lower landing and Ethan and I stacked it. We got a good start but have quite a bit more to do.

Decided to take a little time to stop and smell the gun powder. Everyone was tired on the way home.

X

The five cupola wall panels are complete and have been stacked in the dome. These panels are very heavy. Help loading them and unloading them was very welcome! Dan will cut out the window area after they are installed.

10-12-14

We fitted the pressure treated sill plates to the basement walls.

We fitted the pressure treated sill plates to the basement walls.

After we numbered them all we took them back home to the shop. They will be the bottom of the riser walls.

10-26-14

Dan spent the rest of October cutting all the parts for the riser walls.

Dan spent the rest of October cutting all the parts for the riser walls.

Dan keeps telling me his shop isn't big enough for this project. I just keep nodding and telling him he's doing great. Haha

11-14-14

We spent one of the days of late buck hunting having a brush and wood scrap fire. If you don't get rid of it when you can it will try to take over!

We spent one of the days of late buck hunting having a brush and wood scrap fire. If you don't get rid of it when you can it will try to take over!

OK, so the riser wall construction turned out to be more of a thang than I thought it would be. We have decided to postpone building the dormers and get started on the timber frames as soon as the risers are finished.

The riser walls consist of six spacer panels (to hold the triangles up temporarily then be removed for the openings), four window panels, and ten regular panels.

We added the four (two on each side) widow sliders in the riser walls because the triangle windows are non opening and we want to have some ventilation when needed.

11-23-14

The shop is filling up fast. Dan has two more to make then we have to get them to the dome.

The shop is filling up fast. Dan has two more to make then we have to get them to the dome.

The space at the bottom of the riser wall will receive the floor joists. When the treated sill plate at the bottom gets bolted to the foundation, the entire dome will be well anchored and will not fly somewhere over the rainbow.

X

_________

__________

X

11-30-14

Dan completed the riser walls. Josh, Marty, Danny, & Robbie loaded them on our trailer while they were at our house for Thanksgiving dinner. We took them to the dome and Bruce helped unload them. Their was a little snow at the top of the hill but we made it with no problems!

Dan completed the riser walls. Josh, Marty, Danny, & Robbie loaded them on our trailer while they were at our house for Thanksgiving dinner. We took them to the dome and Bruce helped unload them. Their was a little snow at the top of the hill but we made it with no problems!

12-11-14

The wind has knocked the power out. In the house we have candle light but in the shop.....

The wind has knocked the power out. In the house we have candle light but in the shop.....

Dan has the generator powering two work lights and timber framing continues on.

We got by with one set of saw horses when building the shop frames but two sets certainly would have been nice. Dan is now building the second set and getting reacquainted with timber framing.

X

Dan is making good progress on the saw horses.

Ready for a little assembly.

Another year is almost past. Looking back at pictures and journal entries helps us reflect on this years accomplishments. Not quite as much done as our set goals but enjoyed every minute of the project so I call it a successful year!