2016

We ended last year with 16 of the 18 primary rafters sleeping soundly at the dome.

1-30-16

Our tarps in the driveway covering our timber piles are getting old and beginning to deteriorate.

With the help of a timber moving crew (our dear friends and fam) we put all the timbers that would fit into the shop.

Our tarps in the driveway covering our timber piles are getting old and beginning to deteriorate.

With the help of a timber moving crew (our dear friends and fam) we put all the timbers that would fit into the shop.

With a new tarp, Dan built a tent off the end of the shop.

The timbers too long for the shop are protected under the tent.

Our trailer is loaded with steel post for the dome deck. With the use of Bob P.'s trailer, they loaded the finished timbers in the shop to take to the storage unit.

The storage unit is housing the smaller unfinished timbers and now that the weather has turned (we don't want to transport timbers all the way to the dome in the rain or snow), also some of the finished timbers.

The last two primary rafters, three sill plates, and the twelve crossties.

2-12-16

With the road somewhat passable we took the load of steel posts to the dome. It was a heavy load.

With the road somewhat passable we took the load of steel posts to the dome. It was a heavy load.

Mr. D. Walt says he is very lonely in the shop and can't wait for Dan to stop preparing tax returns and to come play in the shop again!

Back to home page

Now onto tax season...........

4-30-16

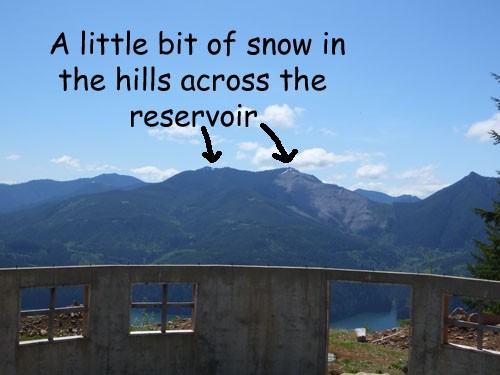

The snow is disappearing fast this year. The mountain already has ridges showing.

The snow is disappearing fast this year. The mountain already has ridges showing.

There was an inch of new snow at the dome six days ago but it didn't last long.

5-1-16

We spent the weekend removing the rest of the pier pad forms and back filling.

We spent the weekend removing the rest of the pier pad forms and back filling.

Hot weekend. Feels like summer is here already.

6-7-16

We haven't been to the dome much since tax

season has been over due to repairs at home.

During the high water this winter Mother

Nature took away some of our river bank. We

filled the holes with fill dirt and smoothed it out

with top soil and had it hydro seeded today. Yaa!, all done but the watering and Dan installed all new sprinkler heads and a new controller so that just means the push of a button.

We haven't been to the dome much since tax

season has been over due to repairs at home.

During the high water this winter Mother

Nature took away some of our river bank. We

filled the holes with fill dirt and smoothed it out

with top soil and had it hydro seeded today. Yaa!, all done but the watering and Dan installed all new sprinkler heads and a new controller so that just means the push of a button.

Meanwhile Dan has been spending mega hours in the shop working on our timbers.

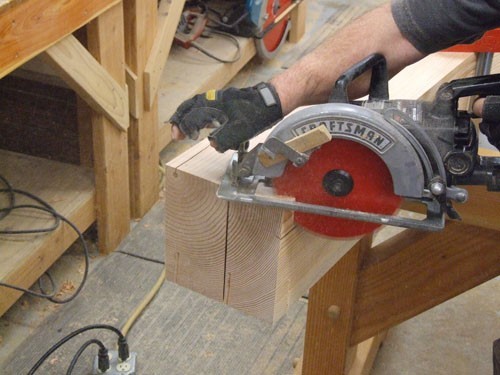

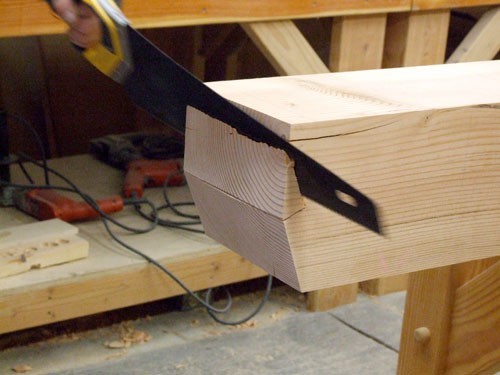

I decided I needed to watch the process from start to finish. So one day I took my camera and perched on a stool in the corner. Even though I already know the time and dedication involved it gave me a new appreciation of the magic that happens in our shop.

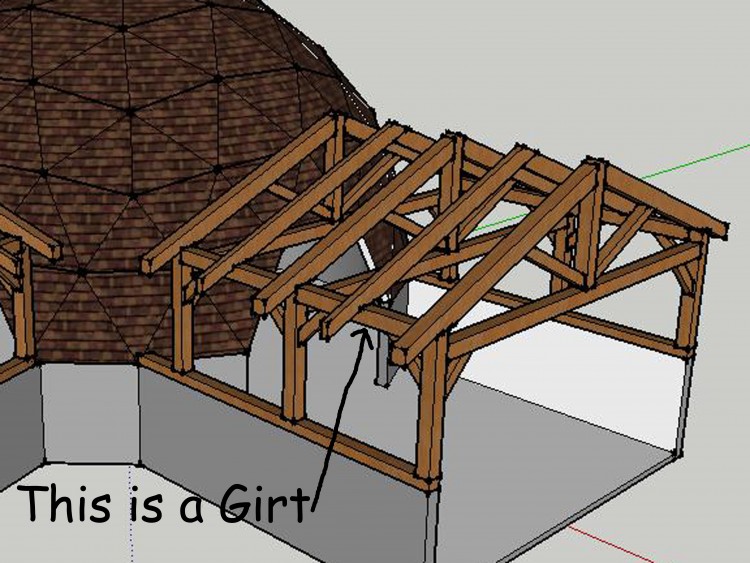

Click on the picture to the right to watch the process of making a girt.

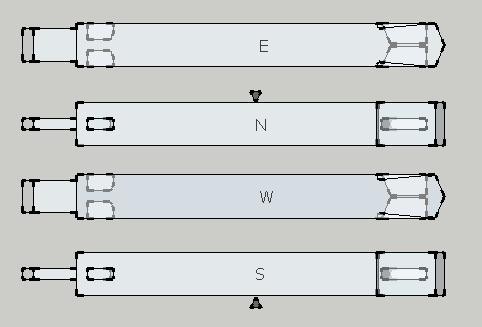

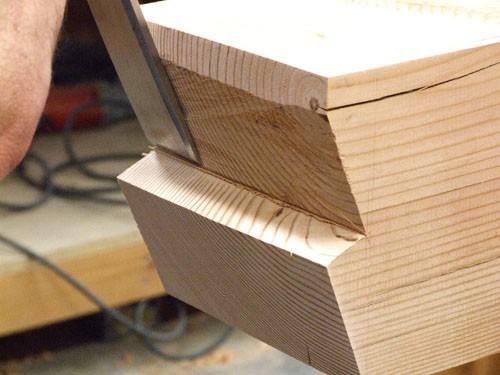

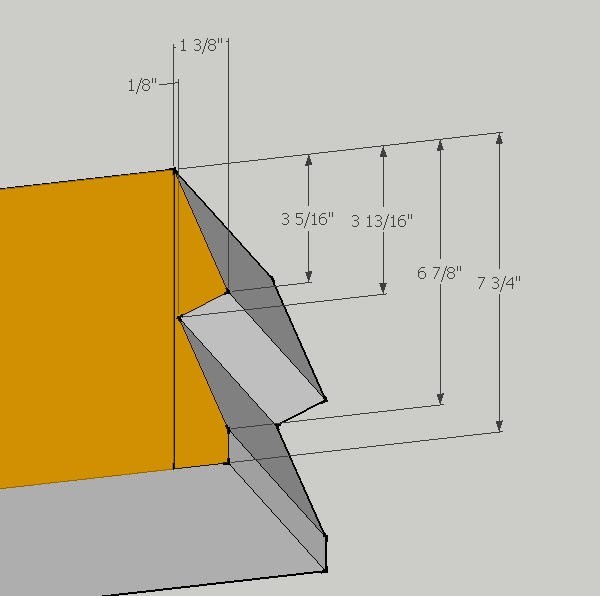

The girts in our frames have a shouldered offset tenon with a partially diminished haunch on both ends, two mortises for the braces, and a step lap rafter seat for the secondary rafter to sit in.

He is working on the girts right now. We need 12 girts (4 per frame).

6-12-16

Bruce had been using two shipping containers for storage but now is building a shop. So Bruce brought one over and parked it next to our shop for us to store timbers in.

Bruce had been using two shipping containers for storage but now is building a shop. So Bruce brought one over and parked it next to our shop for us to store timbers in.

Not a great look but ok for temporary. We are running out of room in the shop with the triangle panels, redwood, and now timbers.

6-15-16

Dan finished the twelve girts.

Dan finished the twelve girts.

Loaded and ready to go to the dome.

The twelve girts seemed to fill the shop at home but looks so small in the container.

6-19-16

Using a wire wheel Dan cleaned the rust off the pier pad bolts.

Using a wire wheel Dan cleaned the rust off the pier pad bolts.

To be on schedule (the time frame we mapped out to be ready next spring) Dan needed to be done with the girts by June 12th. He finished them on the 15th which surprised me because we misjudged the time needed for each one and he had to put in about 21 hours a week to stay close to the schedule.

Next, the king posts. Hopefully all nine completed by July 19th.

Next, the king posts. Hopefully all nine completed by July 19th.

6-29-16

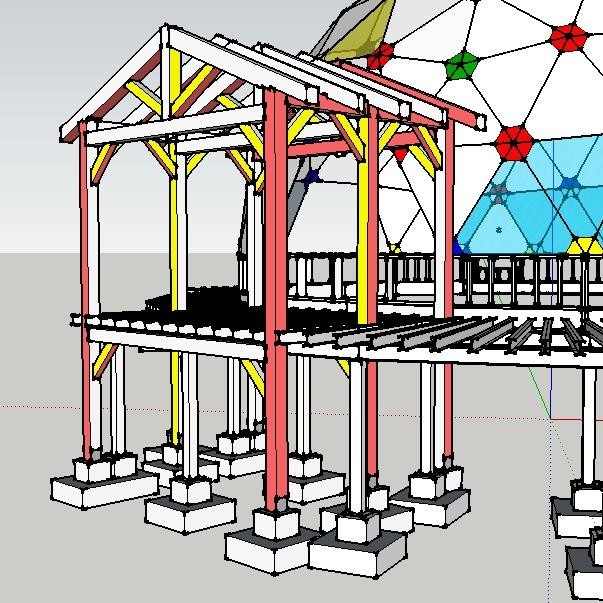

It was time to bring out all the steel posts that we hauled up to the dome in February.

It was time to bring out all the steel posts that we hauled up to the dome in February.

The bottom plates on all the posts (tall and short) got wire brushed, cleaned, primered, and painted two coats of paint.

7-3-16

Bruce came over with his tractor and picked up the posts.

Bruce came over with his tractor and picked up the posts.

He and Dan were able to place them right on the pads.

Dome-henge.

While they were placing posts I added to a small rock retaining wall I had started earlier.

Dan has been busy making king posts.

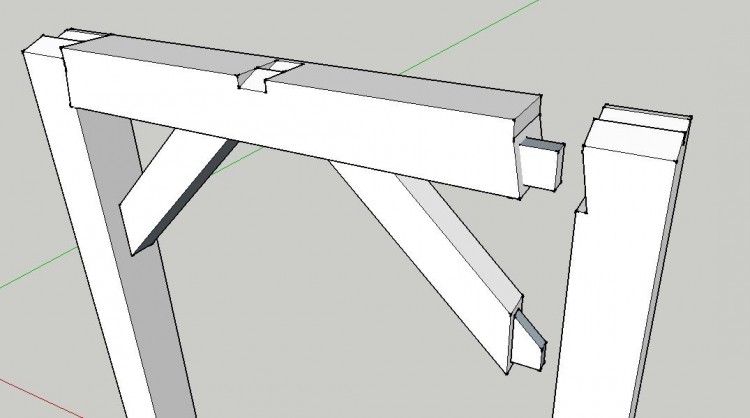

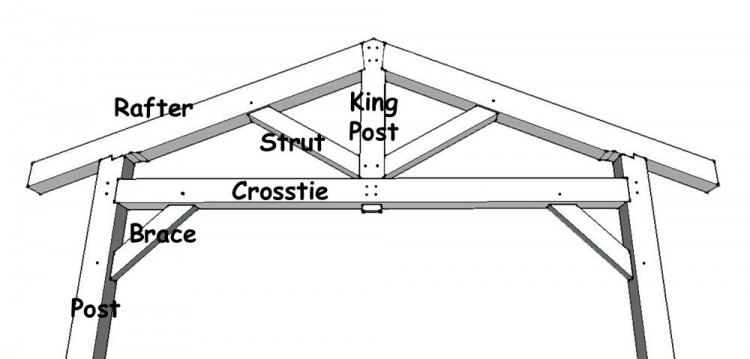

It has a through tenon at the bottom. For structural purposes it would not need to extend past the bottom of the crosstie. Although when it does, it adds architectural interest.

I think the king post is an interesting piece. It has two angled shoulders at the top where the rafters fit giving it a keystone shape.

(This king post is from one of the shop frames)

At first appearance it may seem like the king post is sitting on the crosstie holding up the rafters. But what is really going on is a circle of forces. The rafters are sitting in (and joined by mortise and tenons)the shoulders at the top of the king post. Pinching the king post between them. The rafters can't slide out because of the step lap rafter seat (the notches at the top of the post). And the post can't lean out because they are mortise and tenon pegged to the crosstie. The crosstie can't sag because it is actually being held up by the king post. Add the struts for some rafter support and a couple of braces and you've got some real strength!

Click on the picture to the right to see the making of a king post.

7-17-16

Back at the dome we spent the day making all the deck posts plumb and level.

Back at the dome we spent the day making all the deck posts plumb and level.

The nuts on the bolts under the post plate is used to adjust the posts.

7-31-16

All nine king posts! Finished and ready to go to the dome.

All nine king posts! Finished and ready to go to the dome.

8-20-16

We have timbers stored in storage units, inside the dome, and at home in the shop. It's time to get them all organized inside the container. We want them stacked so that the ones we will need first are on top. That means moving pretty much all of the timbers. How to do this?

We have timbers stored in storage units, inside the dome, and at home in the shop. It's time to get them all organized inside the container. We want them stacked so that the ones we will need first are on top. That means moving pretty much all of the timbers. How to do this?

Well, you get some of this.

And some of these.

Have a man with a plan.

And even though it's the hottest day of the year...

the timbers keep mov'in.

And before you know it...

The timbers are all put to bed.

Thanks Guys!

After the work was done the guys played a little "dome soccer". I think the only rule was to have fun!

8-22-16

One evening Dan and I took the first load of steel deck beams to the dome.

One evening Dan and I took the first load of steel deck beams to the dome.

8-28-16

We took the other load of steel beams up to the dome.

We took the other load of steel beams up to the dome.

We chained the beams to Bruce's tractor bucket and he moved them down close to their assigned spot.

We wrestled the Genie lift (using leap-frogging plywood) down to the posts. Then we got the beam onto the forks and Dan cranked it up to the top of the posts.

By the end of the day we had all the beams up in place.

9-10-16 The six posts for the entry way frame are complete and put in the container.

There is hardly any snow left on the mountain.

Brad starts the project of welding all the deck beams together and to the posts.

10-2-16 Dan starts the last post for the master bedroom frame.

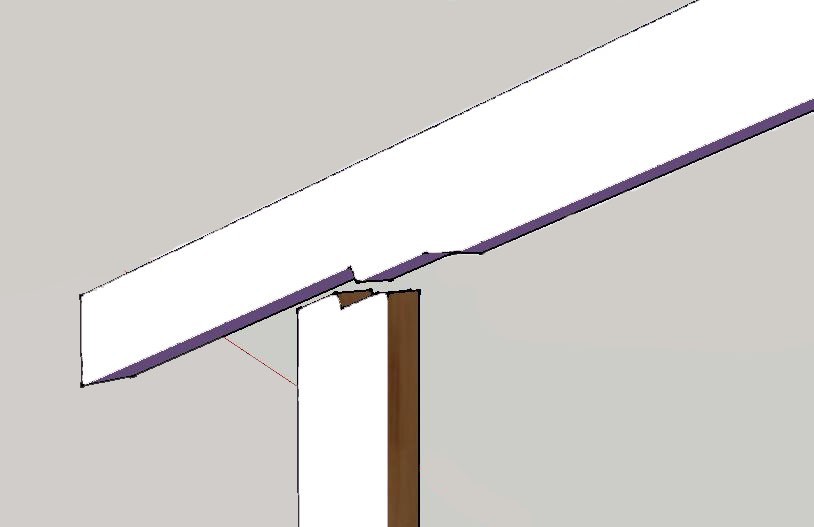

He is working on the step lap rafter seat on the top of the post.

The joinery is complete on all six master bedroom posts, but they still need to be sanded.

10-11-16

A day of no rain. Brad welded more deck beams in place. Nice but cold day. There is new snow on the mountain.

A day of no rain. Brad welded more deck beams in place. Nice but cold day. There is new snow on the mountain.

10-21-16

The weather seams to be changing fast. More snow on the mountain.

The weather seams to be changing fast. More snow on the mountain.

We unloaded a trailer load of steel joists for the deck and headed for the Northwoods cabin. We have the shed/bunkhouse building to reroof.

Hunting season has arrived. We spent the first 3 days hunting then went to town for a load of steel joists.

11-10-16

Dan and Mike hunted together today and after the hunt they unloaded the deck joists. One more load to go.

Dan and Mike hunted together today and after the hunt they unloaded the deck joists. One more load to go.

It's been a heck of a week. Dan's backache developed into shingles. On the way home to his doctor's appointment, a lady came across the center line right at Dan. He swerved and she missed the Suburban but hit the trailer hard.

12-3-16

After settling with the lady's insurance company we got our new trailer today. We picked it up and went to the dome and got our Christmas tree and ladders.

After settling with the lady's insurance company we got our new trailer today. We picked it up and went to the dome and got our Christmas tree and ladders.

It's been several weeks since Dan's felt well enough to really work in the shop. He's done an hour here and there but then the pain returns.

12-14-16

Dan is feeling better, though not completely healed. His is back in the shop and trying to make up some lost time.

Dan is feeling better, though not completely healed. His is back in the shop and trying to make up some lost time.

The posts for the deck timber frame are so long they don't fit in Dan's shop. He moved all his timber framing tools to the long skinny back shop.

Another mortise complete. There are 218 mortises in these three frames. 198 complete, 20 to go!

Now onto shouldering.

12-15-16

I don't think we'll be hauling anything to the dome anytime soon. Our neighbor Bruce sent us this pic from his porch. Five feet and counting!

I don't think we'll be hauling anything to the dome anytime soon. Our neighbor Bruce sent us this pic from his porch. Five feet and counting!

We spent the weekend of the 17th with family and friends witnessing our son Dan wedding his sweetheart.

The next weekend was Christmas. It's been a truly wonderful family season. We are so thankful for all our family and friends.

12-26-16 -back to timber framing...

Dan finished two more long posts. Four down, two more to go.

Dan finished two more long posts. Four down, two more to go.

12-27-16

Robbie came over and helped Dan move the two finished timbers out of the shop and the last two into the shop. These big posts are more than I can help with. Thank you Robbie.

Robbie came over and helped Dan move the two finished timbers out of the shop and the last two into the shop. These big posts are more than I can help with. Thank you Robbie.